> PROGRAM

Plenary Talks

Jianguo Lin

(Imperial College London, UK)

SHORT-BIO...

Jianguo Lin, FREng, FIMechE, FIMMM, FISME, CEng, PhD, is a Professor in the Metal Forming and Materials Modelling Group, Department of Mechanical Engineering, Imperial College London, UK. He obtained his PhD in Mechanical Engineering Department of the University of Sheffield, UK, in 1991.

He is a Fellow of Royal Academy of Engineering (FREng) and joined Imperial College London from the University of Birmingham in 2008 and established a Metal Forming and Materials Modelling Group at Imperial. The Group has 4 research centres and 2 joint research Labs fully funded by industry, and, has an international reputation in developing new metal forming processes, multiscale materials and process modelling theories.

His research expertise is in Metal forming, Materials and Process Modelling. He has published over 300 research papers in refereed international journals and over 20 patents, most of which have been taken by industry. He is a Founder Director of three Imperial spin-off companies (Impression Technologies Ltd, CurvEx Technology Ltd and Multi-X Solutions Ltd), which are resulted from his patented techniques.

Marion Merklein

(Friedrich-Alexander University of Erlangen-Nürnberg, Germany)

SHORT-BIO...

Marion Merklein is professor of manufacturing at the department of mechanical engineering at Friedrich-Alexander-University Erlangen-Nuremberg (FAU), Germany. She obtained a PhD in mechanical engineering from FAU in 2001, the habilitation in mechanical engineering from FAU in 2006.

She is Fellow of the International Academy for Production Engineering (CIRP), member of the Standing Advisory Board of ICTP – The International Conference on Technology of Plasticity and received prizes and awards, e.g., the Gottfried Wilhelm Leibniz Award from the DFG, 2013, as well as the SME Frederick W. Taylor Research Medal, 2024.

She was dean of the faculty of engineering from 2011 to 2015, is member of the senate from the German Research Foundation (DFG). Additionally, she is member of different national academies, e.g., National Academy of Science and Engineering (acatech), Berlin-Brandenburg Academy of Sciences and Humanities (BBAW) and German National Academy of Sciences Leopoldina.

Her research interests are focused on metal forming, joining by forming technologies, material characterisation and modelling and digitization. She is author of two books, (inter)national patents and more than 600 papers in international journals and conferences.

Sandrine Thuillier

(Université de Bretagne Sud, France)

SHORT-BIO...

Sandrine Thuillier is full professor in mechanical engineering at Université Bretagne Sud (Lorient, France). Her research activities are dedicated to the experimental characterisation of the mechanical behaviour of materials at room and warm temperatures, mainly metallic sheets. She also focuses her efforts on material parameter identification by inverse methodologies, and with heterogeneous tests, as these parameters are an important input to the numerical models based on elasto-visco-plasticity, anisotropic yield and macroscopic rupture. Finally, she applies her scientific skills to metal forming and joining processes, such as deep drawing, hemming, surface defects, bending, twisting and clinching.

She chaired the IDDRG (International Deep Drawing Research Group) conference in June 2022 in Lorient. She is a member of the board of directors of the ESAFORM association and deputy-secretary of this association. Moreover, she is associate editor for the journals “Mechanics & Industry” and “International Journal of Material Forming”. She has co-authored more than 170 papers published in peer-reviewed international journal or presented at international conferences.

Shi-Hong Zhang

(Institute of Metal Research, Chinese Academy of Sciences, China)

SHORT-BIO...

Leader of advanced metal forming technology group, Institute of Metal Research, Chinese Academy of Sciences (IMR/CAS), China. Director of Engineering Research Centre for Precision Copper Tubes (ERC/PCT), Chinese Academy of Sciences.

Prof. Zhang received his PhD from Harbin Institute of Technology (HIT), China in 1991. He worked as post-doctor, associate professor and full professor at HIT from 1991 until 1999. In between 1995 and 1998, he joined DANFOSS A/S and Aalborg University, Denmark as a researcher. From 1999 to-date he is full professor at IMR/ CAS.

Prof. Zhang has published more than 350 journal papers (around 200 and 150 papers published in international and Chinese leading journals, respectively), presented more than 80 conference papers and got around 90 patents. He obtained A.M. Strickland Award from Institution of Mechanical Engineers (IMechE), London, UK in 2011. He got the First Zienkiewicz Honorary Award at NUMIFORM2016 in France. He also got the National Prize for Scientific Progress of China in 2015. He is the Member of Stirring Committee of NUMIFORM Conferences and also Executive member of IDDRG. He organized NUMIFORM2013 in Shenyang and IDDRG2015 in Shanghai as the Chairman. He is Vice President of Chinese Society for Technology of Plasticity (CSTP).

His research interests include Development of Advanced Metal forming Technologies (Impact hydroforming of sheets and tubes, production of copper tubes, sheet, and wires); Finite Element Modelling of Metal Forming processes; Predicting of rolling texture and anisotropic behaviour by VPSC and CPFEM; High strain rate deformation and fracture Mechanics.

Mathias Liewald

(University of Stuttgart, Germany)

SHORT-BIO...

Prof. Dr.-Ing. Mathias Liewald MBA, born in 1960, studied Mechanical Engineering at Technical University of Dortmund. In 1985 he joined the Chair for Metal Forming at his university as scientific assistant, in 1990 he obtained his doctorate in the field of Sheet Metal bending technologies (Title of The-sis: „Strategies on process control of sheet metal bending processes supported by adaptive control“).

From 1991 to 1994 he has been working at Daimler-Benz AG (Sindelfingen/Germany) as a group leader in press shop technology, process optimisation and high strength sheet metal material manufacturing. By the year 1995 he left Daimler-Benz company and occupied the position as a plant manager for large panel production with Gebr. Wackenhut GmbH (Nagold/Germany).

From 1997 he occupied the position as Plant manager of the ThyssenKrupp Nothelfer site located in Lockweiler/Germany) being in charge for 1000 employees in the year 2000. In the same year he was nominated as a vice president “Dies International” being responsible for all die manufacturing activities of ThyssenKrupp Nothelfer Group.

In April 2005 he was appointed as a Full Professor and director at the Institute for Metal Forming Technology (IFU) at the University of Stuttgart. Prof. Liewald is active in multiple scientific boards and international organisations. He is also quite active as an Associate Fellow in the International Academy for Production Engineering (CIRP) as well as in the International Cold Forging Group (ICFG). He is also heading several Non-for profit organisations and two Foundations. He holds numerous patens and published more than 500 papers.

Bart Carleer

(AutoForm, Switzerland)

SHORT-BIO...

Dr. Bart Carleer has been the Corporate Technical Director of AutoForm since 2008. He holds a Ph.D. in Mechanical Engineering and, within the context of his dissertation, focused on the application of forming simulation for deep drawing. Before coming to AutoForm in 2003, he worked at steel and aluminum manufacturer Corus for over five years, with his last position as department head for sheet metal and hydroforming at Corus Research, Development and Technology. At AutoForm, he is responsible for the technical supervision of AutoForm products as well as training, support and technical product management.

Carlos Saraiva

(MCG – Mind for Metal, Portugal)

SHORT-BIO...

Carlos Saraiva, is currently Managing MCG AUTOMOTIVE Business Area, which is the company area that mainly focuses in product co-development, process development, industrialization and mass production of automotive products based on sheet metal that have stamping, welding and coating as its main manufacturing processes.

He has an academic background as Aerospace Engineer from Instituto Superior Técnico at Universidade de Lisboa.

The relevant professional background over the past 25 years has been crossing a few areas such as Quality Control, Stamping and Welding Process Development and Tool Design, and, more recently, in more broad areas such as Engineering and Project Management, Business Development.

Currently, and since 2022, managing the Automotive Business Area that incorporates Business Development, Sales, Engineering, Industrialization, Production, Maintenance, and Development Programs towards innovation in both Manufacturing Processes, Production Management & Leadership and in Sales/Business Development Activities.

Vasco Burguete

(JDEUS/DENSO, Portugal)

SHORT-BIO...

Carlos Saraiva, is currently Managing MCG AUTOMOTIVE Business Area, which is the company area that mainly focuses in product co-development, process development, industrialization and mass production of automotive products based on sheet metal that have stamping, welding and coating as its main manufacturing processes.

He has an academic background as Aerospace Engineer from Instituto Superior Técnico at Universidade de Lisboa.

The relevant professional background over the past 25 years has been crossing a few areas such as Quality Control, Stamping and Welding Process Development and Tool Design, and, more recently, in more broad areas such as Engineering and Project Management, Business Development.

Currently, and since 2022, managing the Automotive Business Area that incorporates Business Development, Sales, Engineering, Industrialization, Production, Maintenance, and Development Programs towards innovation in both Manufacturing Processes, Production Management & Leadership and in Sales/Business Development Activities.

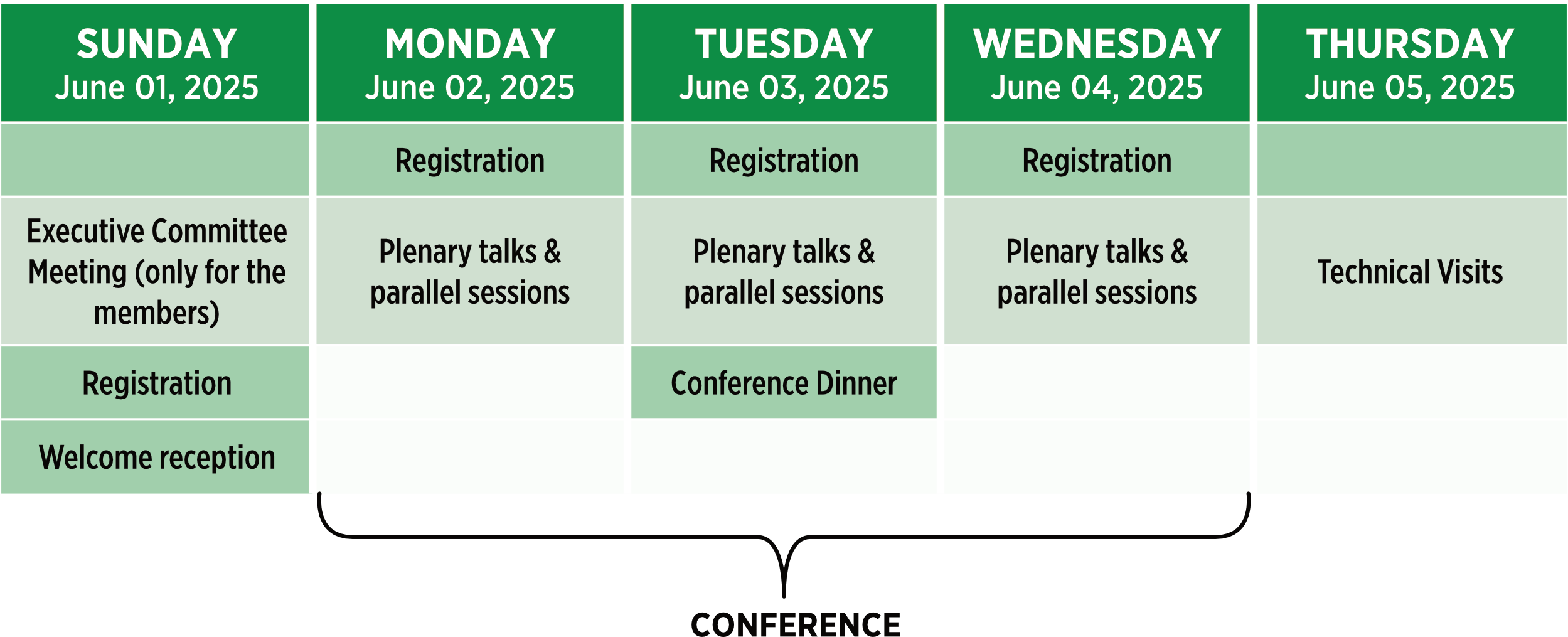

Technical visits

Two Technical Visits will take place on June 05. Each visit is limited to 50 persons. Therefore, the earlier the registration takes place for the technical visit, the greater the probability of being able to join the visits.

The busses will depart at 09:00 a.m. from the IST and return around 01:00p.m.

MCG

With over 73 years of existence, MCG is a manufacturing company that is dedicated to the development and production of solutions and products based on metal and other new-generation composite materials. We present an innovative vision in product design, production, and supply chain integration, prioritizing early-feasibility assurance and total cost optimization. We supply products and solutions to some of the largest OEM and TIER 1 manufacturers for automobiles and trains in the world, in addition to being present in other production areas.

With more than 100 years of accumulated experience and expertise, JDEUS develops its activity in the thermal systems area for automotive Industry. The company is very well known and recognized by its advanced know-how on research and development (R&D) and by its capacity to design, manufacture and supply heat exchangers with very high quality and performance, which are used by the most important car brands and manufacturers.

JDEUS is currently located in Samora Correia, 40 km from Lisbon. With 500 associates and 20.000 m2 of covered area in the facilities, JDEUS engineering laboratories and production equipment rely on state of the art and cutting-edge technology, including aluminium stamping.

JDEUS business plan aims for a solid and ambitious growth, built upon people safety, product and process quality, operation sustainability and social development of the community in which it is located.

© Copyright 2024. All Rights Reserves.